IKO Machinery For Specific Application

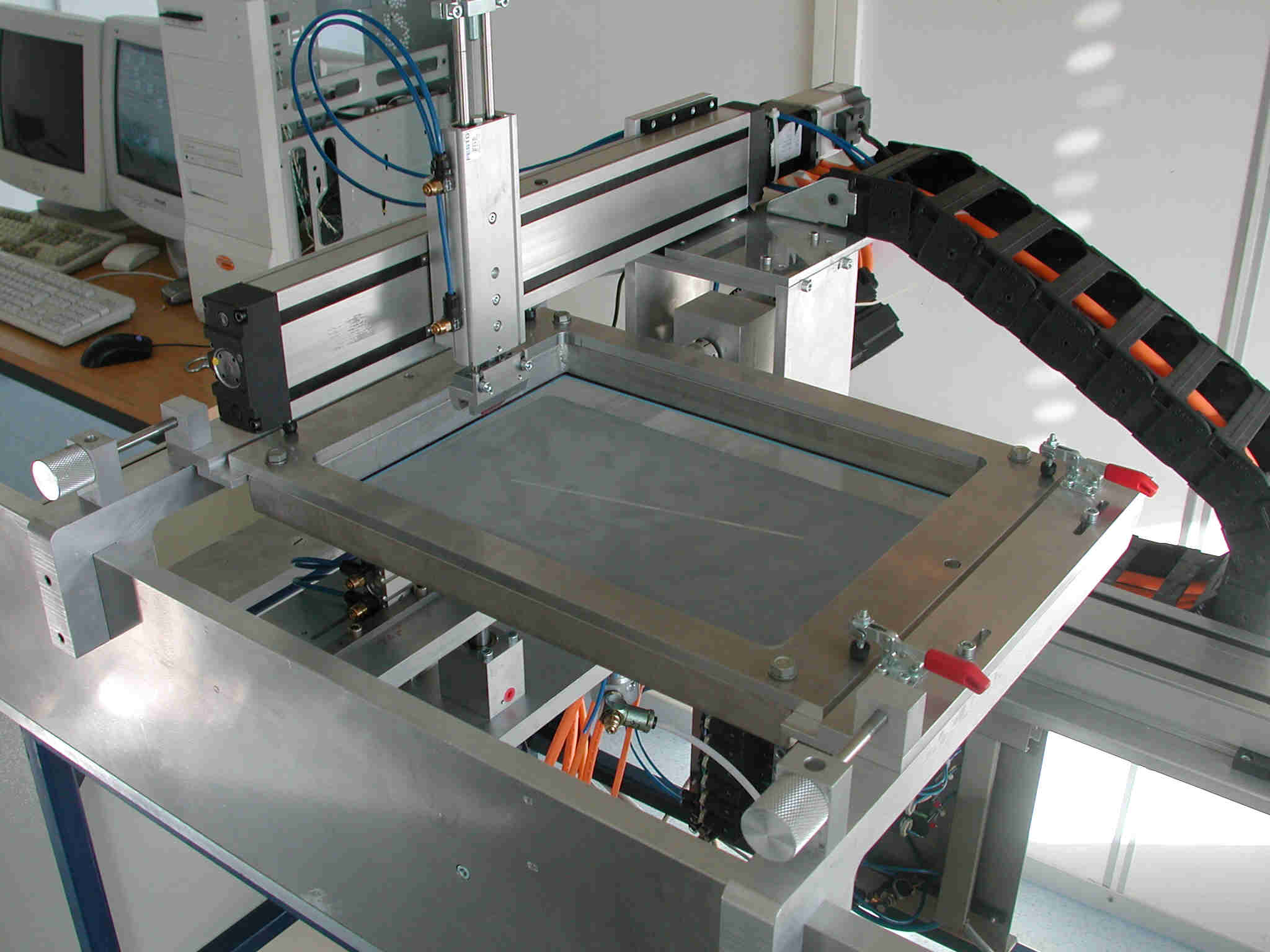

Tube Screen Printer IKO-T-620-80200

The IKO-T-620-80200 -Screen Printer is an ideal solution for high precision screen printing on tubes and other cylindrical items. It is designed especially for thick film applications, which require a high level of screen printing accuracy. The IKO-T-620-80200 - Screen Printer is a modular system which can be used in research and development as well as in high volume production environments. The basic semiautomatic IKO-T-620-80200 model can be easily upgraded to a fully automated inline production machine which is characterized by a user-friendly operation, short set-up times and high degree of versatility. An easy exchangeable clamping system provides to print on tubes of varying diameter and different materials. A soft clamping system enables the application of tubes of even delicate material. An additional mode of driving the squeegee enables also the printing of spirals.

The IKO-T-620-80200 printer concept provides a cost effective solution for your screen printing needs.

TYPICAL APPLICATIONS:

|

|

|

GENERAL DESCRIPTION

Squeegee traverse and tube movement are performed by speed controlled motors which provide a fast printing cycle and a high positioning accuracy (Optional)

SPS control modes and pneumatic valves

Pneumatic soft clamping system

Precision squeegee adjustment to tube axis

Anti-backlash fine pitch adjustment for screen registration, with self locking mechanism

Adjustable snap-off distance

All moving mechanisms are mounted on radial and linear bearings and hardened precision ground shafts

Optoelectronic registration of start position of tube (Optional)

TECHNICAL DATA FOR IKO-T-620-80200

|

OPTIONS:

|

IKO has a customer oriented philosophy. Each machine will be adopted to customer’ s specific requirement. Don’t hesitate and contact us for discussing your specific application.